MBL’s process starts immediately after harvesting Laminaria hyperborea from the sea and ends with the creation of high value products for established uses in medicines, food, personal care and a varied mix of industries.

The key to MBL’s success lies in its lateral thinking approach. The traditional approach to extracting any natural product, like alginate, is to try to extract it from its surrounding biomass e.g. by dissolving it out of its seaweed host. MBL thinks differently - its approach is to systematically DECONSTRUCT the biomass so that each chemical component can be sequentially removed then individually recovered.

So, instead of trying to extract alginate from its biomass host, MBL removes all the other components, sequentially, until only the alginate and cellulose are left (as an intermediate product that MBL calls CTS). Then it dissolves the alginate out of this CTS leaving raw seaweed cellulose fibre as its residual product. In this way, MBL can achieve over 90% utilisation of the original biomass instead of the 15% achieved by traditional methods.

Traditional processes for extracting alginate are also compromised by the seaweed’s natural defence chemicals (polyphenols, pigments) as these can co- extract along with the alginate and make the resulting product useless. This problem is mitigated in traditional processes by pre-treating the seaweed with formaldehyde before extraction; this converts these defence chemicals into an insoluble, polymeric complex that is “locked in” to the seaweed’s physical structure allowing the alginate to be dissolved out without co-extracting the defence chemicals.

However, as well as facilitating the alginate extraction process, the creation of these polymer complexes in the seaweed structure, creates another problem as the fibrous residue (after alginate extraction) cannot be used as a source of other products; it is simply a waste product that must be discarded. In contrast, the fibrous residue from MBL’s formaldehyde-free process is a very valuable product in its own right – MBL’s seaweed cellulose.

This formaldehyde-based traditional process is at the heart of the entire world’s alginate industry However, given today’s knowledge of formaldehyde’s toxicity, its continuing use is unacceptable and elimination of formaldehyde is a critical strategic imperative for the future of the industry.

The problem above was MBL’s start-point – how could it deconstruct seaweed into its individual components to recover multiple products without having to use formaldehyde to protect the alginate? Its proprietary, patented process is the solution.

Using the example of Laminaria hyperborea, the first step in MBL’s process, conducted as soon as possible after harvesting, is the physical separation of the seaweed into its three parts – holdfast (haptera), stem (stipe) and leaves (frond). The richest source of high value MBL end products is in the stem of the plant and MBL’s harvesting method maximises the amount of stem recovered by selectively harvesting larger, older plants (which have the largest stems) leaving smaller, younger plants behind to continue growing. The leaves, which are younger (they regenerate each year) contribute additional high value products while the holdfast, which is more challenging to process, is best suited to lower value applications.

MBL then uses a series of proprietary, patented physical and chemical processes to convert the seaweed stem into its unique light-coloured, fibrous intermediate CTS.

Harvested Laminaria hyperborea

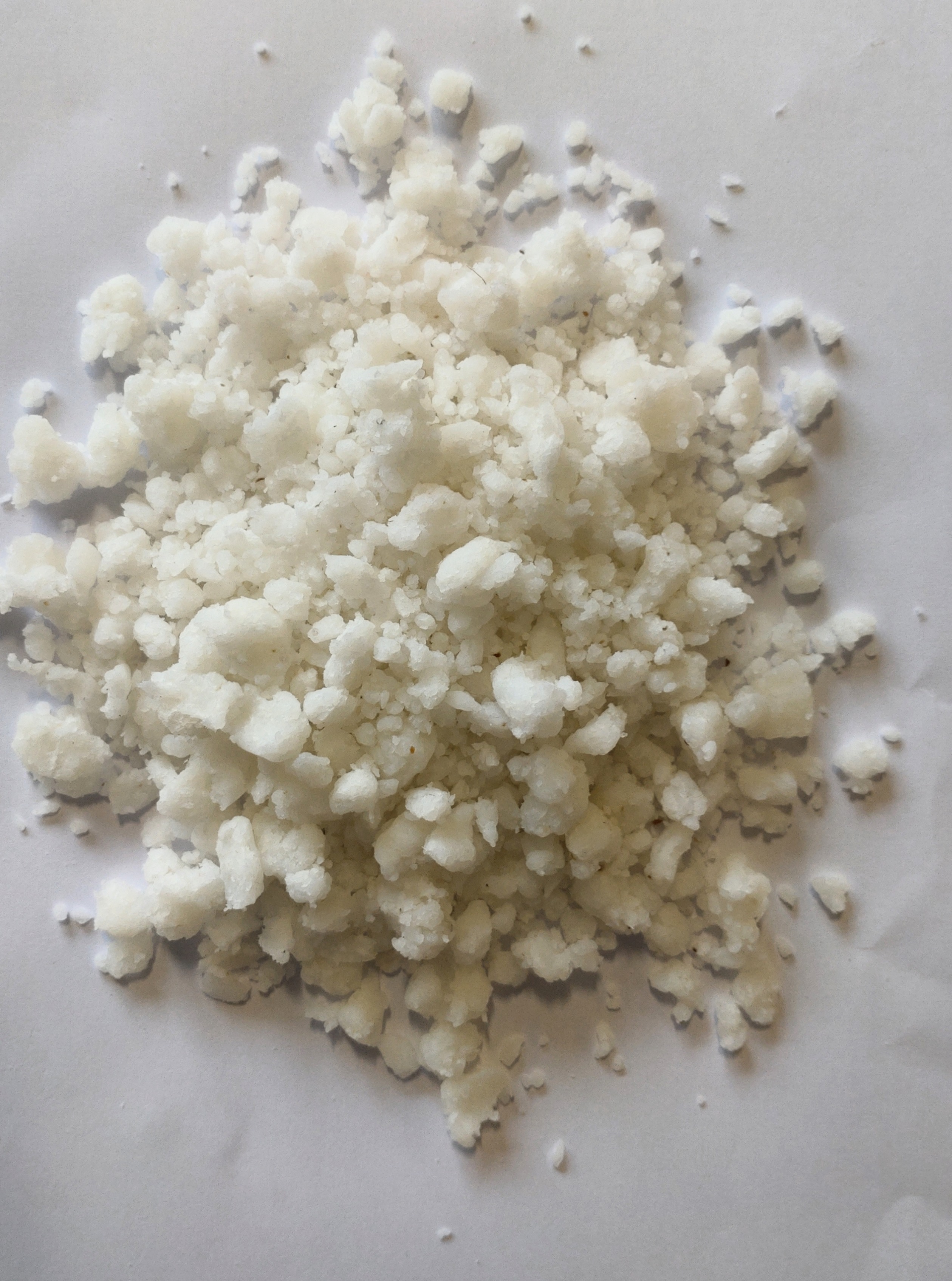

CTS fibre intermediate

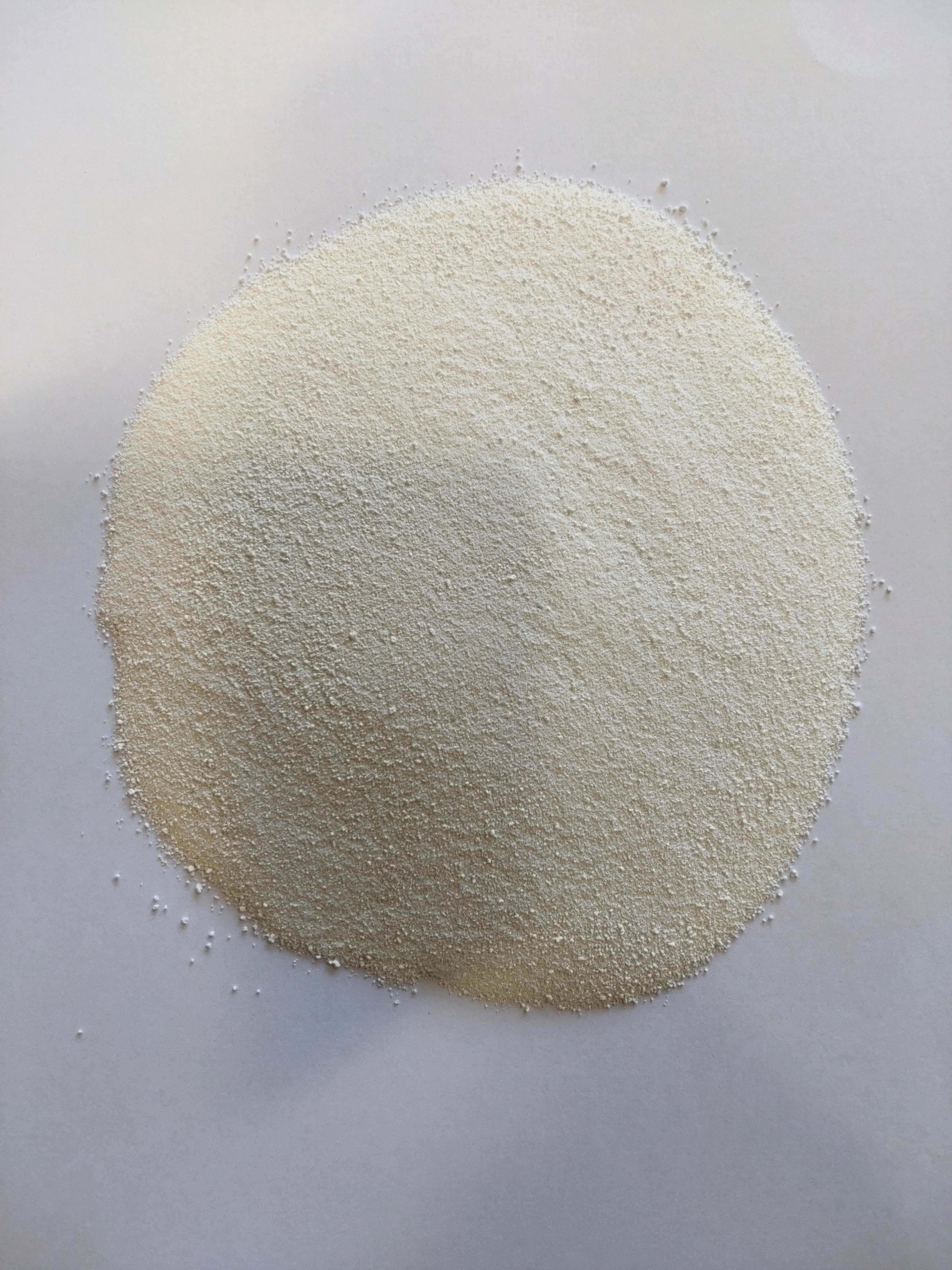

This fibre is a concentrated, stabilised complex of the alginate and cellulose components of the original seaweed stem; all of its other components – including salts, other biopolymers (e.g. fucoidan), proteins, polyphenols etc – have already been removed sequentially so that they can be individually recovered, leaving the alginate/cellulose CTS complex behind. MBL’s CTS then becomes the feedstock for extraction (a milder, faster version of traditional processes that uses less energy, chemicals and water) in which the alginate is dissolved to leave the insoluble cellulose behind. Unlike traditional processes which create a valueless waste – a mix of cellulose, proteins, polyphenols, pigments, and seaweed debris - MBL’s process residue is almost pure cellulose, which then becomes a feedstock for an even more valuable product unique to MBL’s process – MBL seaweed nanocellulose.

Traditional Process Residue

MBL Process Alginate Liquor

MBL Process Residue (Cellulose)

Nanocellulose

Once harvested, brown seaweed deteriorates rapidly but MBL’s technology now enables it to be stabilised and concentrated as CTS fibre, which has an extended shelf life and creates the opportunity to expand the scope of alginate-only plants into multi-product seaweed biorefineries. This invention can transform the structure of the alginate-based seaweed products industry.

Adopting MBL’s process will allow current (or new) alginate producers to future-proof their business against likely restrictions on formaldehyde use. They can achieve industry leadership by being “ahead of the wave” on this and by exploiting the wider product portfolio enabled by MBL’s technology.

MBL’s ideas and technology are protected through patents, trade secrets and secrecy agreements with its partners. It holds extensive patents over its technology in multiple countries.